What's CNC Turning

CNC Turning Basics

What is CNC Turning?

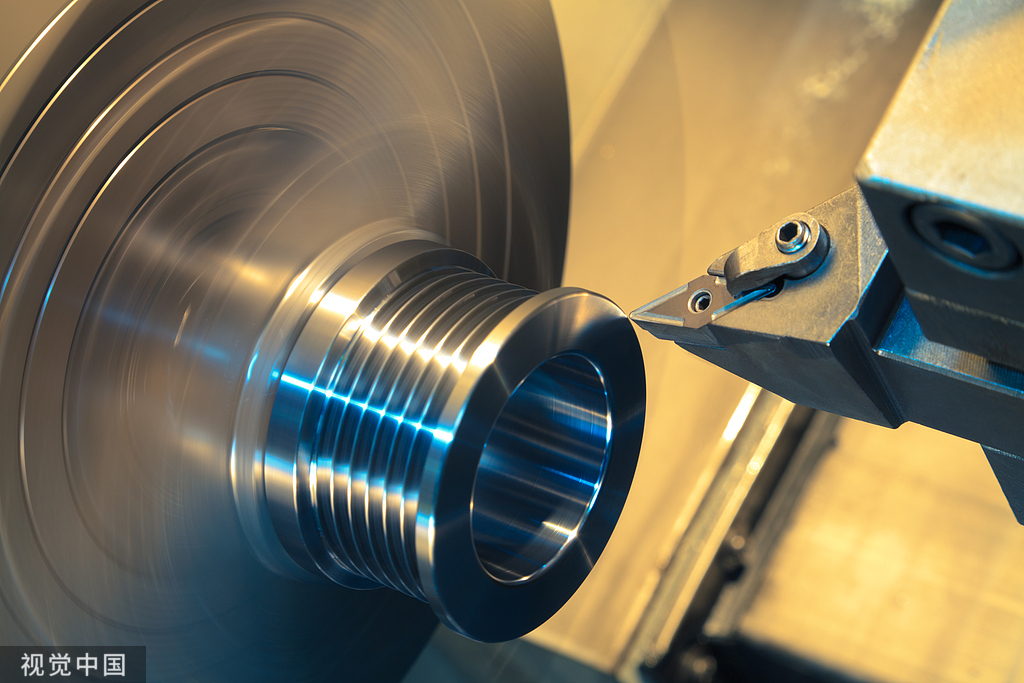

CNC turning is a subtractive manufacturing process in which pieces of material are rotated as a machine tool is fed to the piece, removing material to create a finished piece. It is primarily used to manufacture parts that are cylindrical in nature.

What Shapes Can CNC Turning Make?

Turning is a versatile machining process capable of making a wide range of profiles depending on the turning process used. The functionality of lathes and turning centers allows for straight turning, taper turning, external grooving, threading, knurling, boring, and drilling.

Generally, lathes are limited to simpler turning operations, like straight turning, external grooving, threading, and boring operations. The tool turret on turning centers allows the turning center to complete all the operations of a lathe as well as more complex operations, such as drilling off the axis of rotation.

CNC turning can produce a wide range of shapes with axial symmetry, like cones, cylinders, disks, or a combination of those shapes. Some turning centers are even capable of polygonal turning, using special rotating tools to create shapes like a hexagon along the axis of rotation.

What are the Benefits of CNC Turning?

CNC machining is far better than manual machining for a few specific reasons:

Accuracy: Programming a CNC to complete a job creates a consistent and accurate cut to ensure product quality. It can be repeated over and over in the exact same manner.

Cost Effectiveness: The cost of hiring a person to manually machine parts at scale is far more expensive than having a machine do it, as a machine will not tire, does not need lunch breaks, and can, theoretically run 24/7.

Speed: CNC turning can churn out hundreds and hundreds of parts while retaining a consistent end product.

What is the Difference Between CNC Turning and Milling?

While CNC turning rotates the part for cutting, CNC milling rotates the tool to cut the part.

Going further, CNC turning will typically be used for cylindrical parts, as you rely on the part itself to rotate and create the friction to remove material when the cutting tool is placed against it.

On the other hand, CNC milling can create more complex parts as it is the cutting tool (rather than the material) that is spinning.

What Hongyi Can do for you?