Battery Contact Introduction

Battery contacts are critical components that facilitate the flow of electrical current between a battery and the device it powers. They are designed to ensure a secure and efficient connection, playing a vital role in the performance and safety of battery-powered devices.

Manufacturing Process:

The manufacturing process of battery contacts involves several intricate steps, starting from material selection to final assembly. Key processes include:

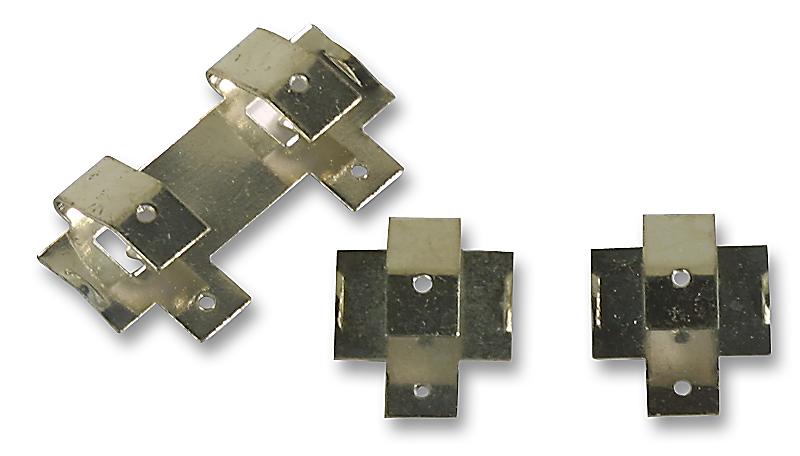

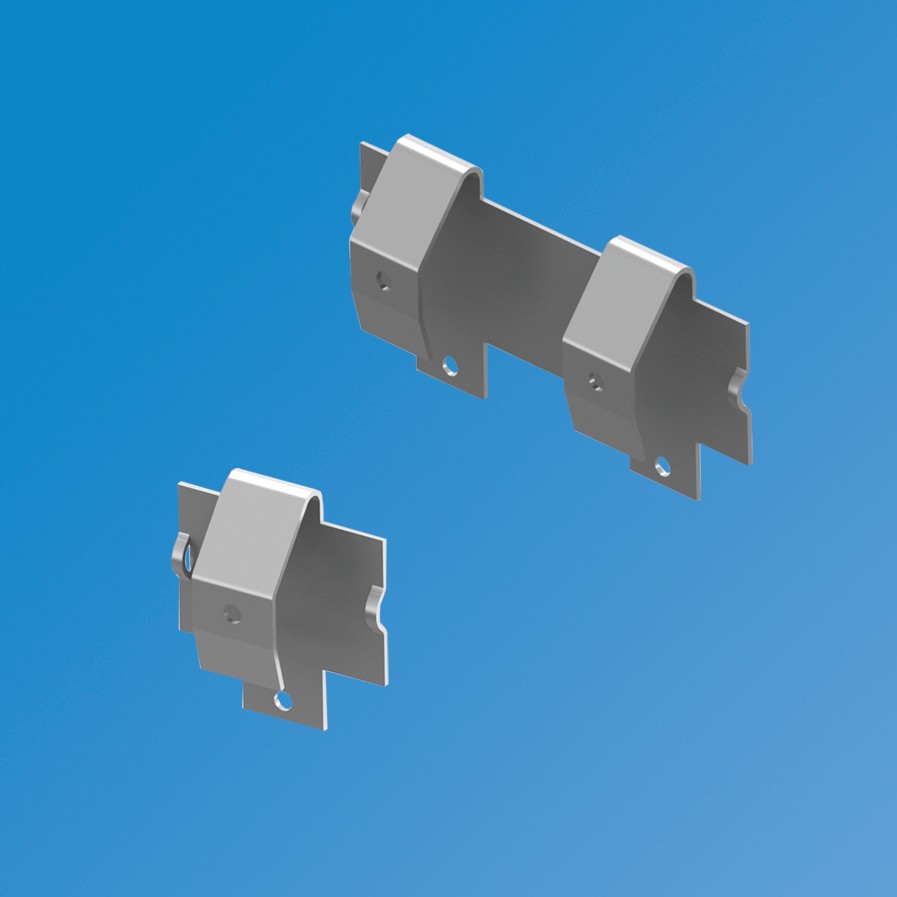

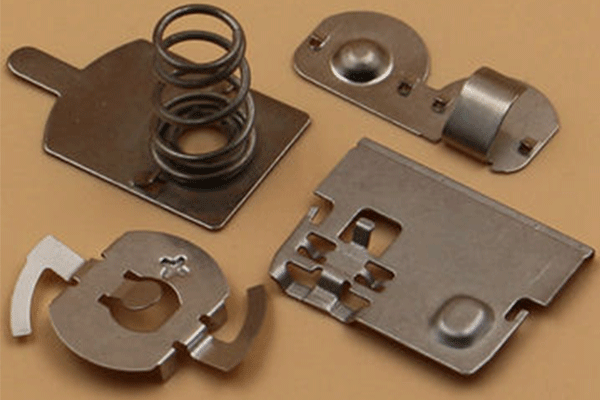

Metal Stamping: Battery contacts are often made through a metal stamping process where metals are cut into desired shapes and sizes. This process is irreversible, making the design pattern crucial before execution

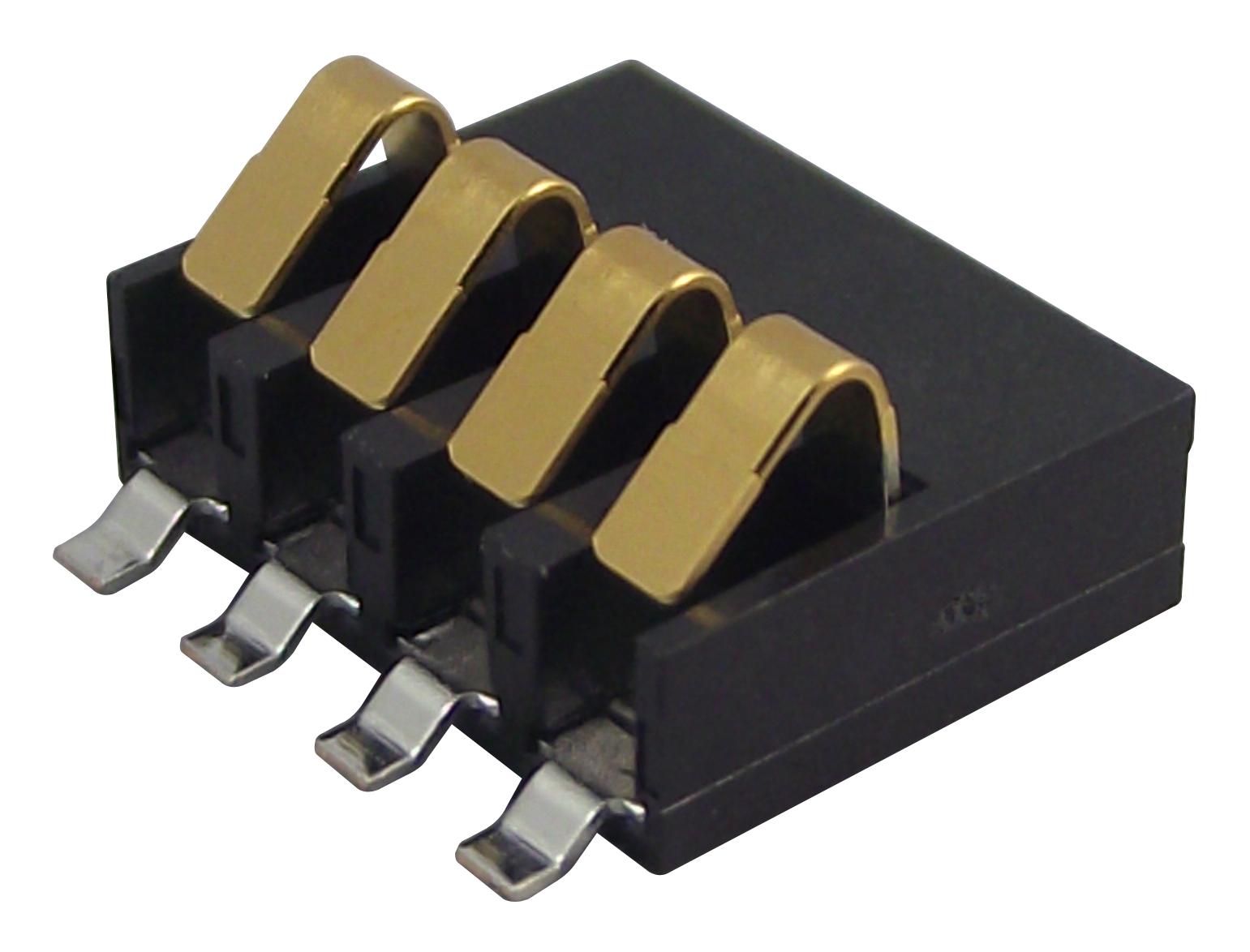

Plating: After stamping, materials are plated with other metals to achieve desired performance characteristics. Plating involves adding a layer of metal to enhance properties such as conductivity and corrosion resistance

Assembly: The contacts are assembled with other battery components, ensuring precise fit and functionality. This step requires careful handling to avoid contamination and ensure uniformity

Materials:

Battery contacts can be made from a variety of materials, each with unique properties:

Nickel-plated materials prevent corrosion of connections

Steels mixed with chromium and nickel offer strong resistance and anti-corrosion qualities

Gold plate provides environmental ruggedness and can withstand various conditions

Beryllium copper is known for its strength and electrical conductivity, making it suitable for harsh conditions

Phosphor bronze offers strength, corrosion resistance, and high conductivity

Brass can be mixed with other materials to enhance toughness

Gold is an excellent conductor and works well for battery contacts due to its high metallic conductivity

Silver plating offers high electrical conductivity and is easier to maintain and solder

Tin plating is soft, easy to stamp, non-toxic, and an excellent electrical conductor

Copper plating is used to coat other metals and is easy to solder

Zinc plating is used to combat corrosion

Surface Treatments:

Surface treatments for battery contacts include plating with metals like nickel, gold, silver, and tin to enhance properties such as conductivity, corrosion resistance, and environmental ruggedness

Applications:

Battery contacts are used in a wide range of applications, from small portable electronics like smartphones and laptops to larger devices such as electric vehicles and industrial equipment. They are essential in ensuring the reliable and safe operation of these devices by providing a stable electrical connection

In summary, battery contacts are meticulously designed and manufactured to meet the specific requirements of various battery-powered devices. Their materials and surface treatments are carefully selected to ensure optimal performance, durability, and safety.