Introduction of Single Punch Die Stamping

What is a single punch die?

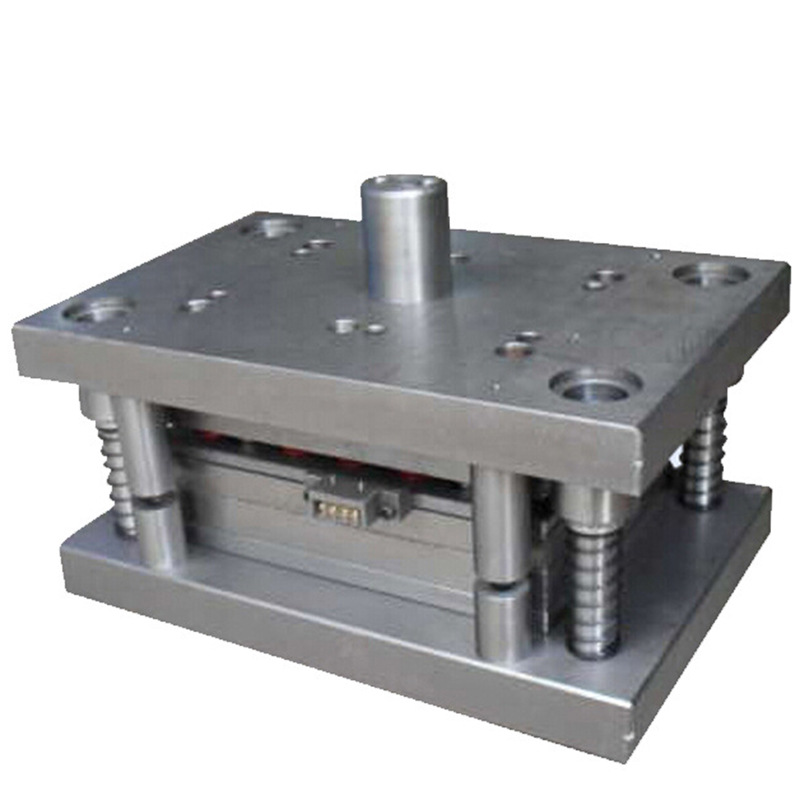

A single punch mold is composed of a concave mold and a punch mold or multiple concave molds and multiple punch molds. Each punch only completes the forming of one punching hole or one shape because its structure and function are designed and designed for a specific process. Manufactured and cannot be applied to other processes. Usually used for small or medium-scale production, especially for situations where the punching position or shape needs to be changed frequently. It can be flexibly adjusted and replaced during the production process, and the manufacturing cost is low. It is suitable for the production of small batches of metal stamping with relatively simple processes.

How does a single punch die work?

First, place the metal plate to be punched in the working area of the single punch die. The workpiece is often clamped to ensure stability during the stamping process. The punch of the single punch die descends, exerting impact force on the metal workpiece. Form the desired hole or shape. After the impact is completed, the punch will be lifted away from the workpiece to prepare for the next stamping. Then manually remove the workpiece and repeat the above operation.