Spring Manufacturing Industry Introduction

Springs are critical components in a wide array of mechanical systems, playing a vital role in providing mechanical support, absorbing shock and vibration, storing and releasing energy, and maintaining equilibrium in various systems. The spring manufacturing industry is a dynamic sector that encompasses the design, production, and finishing of springs used across industries such as automotive, aerospace, medical, electronics, and more.

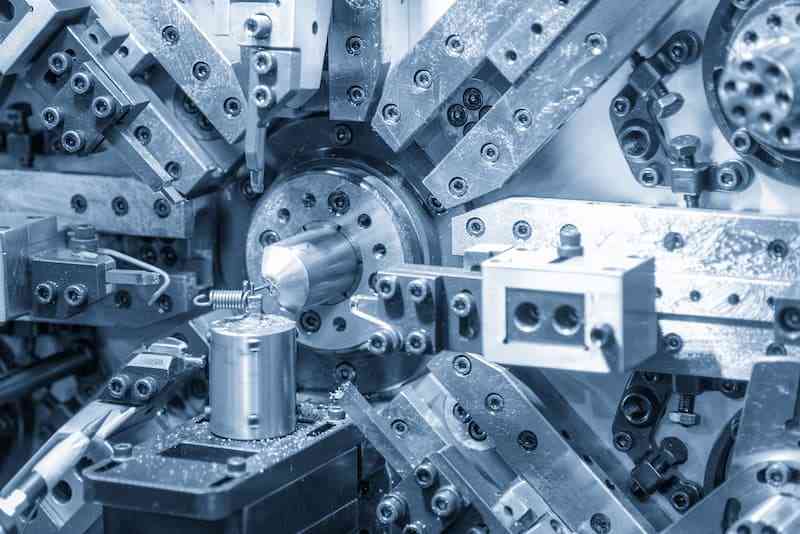

Spring Production Process

The manufacturing of springs involves a series of meticulous steps that ensure the production of high-quality and reliable springs. The process generally includes:

Material Selection: The choice of material is crucial and depends on the spring's expected usage and operating environment. Stainless steel is often preferred for its strength and resiliency, but other materials like titanium, bronze, and nickel alloys are used for specific conditions such as corrosion resistance or high-temperature applications

Winding: Springs are formed by winding wire around a shaft or mandrel. This is typically achieved using automated equipment with computer numerical control (CNC) technology, which ensures quality, accuracy, and efficiency

Heat Treatment: After forming, springs undergo heat treatment to relieve stress caused by coiling. This process enhances the spring's mechanical properties by altering its crystalline structure, leading to greater durability, increased temperature resistance, and improved ductility

Finishing Touches: Additional operations such as bending, trimming, forming, tumbling, and buffing may be performed post-heat treatment, depending on the spring type and geometry

Spring

Classification

Springs are classified based on their function and design:

Compression Springs: Designed to absorb compressive forces.

Tension Springs: Designed to absorb tensile forces.

Torsion Springs: Designed to resist twisting forces.

Constant Force Springs: Provide a nearly constant force over a given deflection.

Belleville Springs: Conical or barrel-shaped washers that function as springs

Materials for Spring Manufacturing

Springs can be made from a variety of materials, with the most common being:

High-carbon Steel: Economical and suitable for a wide range of loading requirements.

Stainless Steel: Common in applications requiring corrosion resistance.

Specialty Alloys: Such as nickel-based alloys, used in demanding mechanical environments for their high strength and heat resistance

Surface Treatments

Surface treatments are essential for improving the longevity and functionality of springs. Common techniques include:

Plating: Enhances corrosion resistance, wear resistance, and appearance. Common metals used include zinc, nickel, chrome, gold, and silver

Heat Treatment: Modifies mechanical properties like strength and toughness

Barrelling: Improves surface quality by removing burrs and sharp edges, reducing friction and wear

Applications of Springs

Springs are used in a multitude of applications across various industries:

Automotive: Suspension systems, clutches, and brake systems.

Aerospace: Landing gear systems and control mechanisms.

Medical: Pacemakers, orthopedic implants, and surgical tools.

Electronics: In devices like pacemakers and other medical equipment

Market Prospects

The spring market is expected to grow due to several key opportunities and trends:

- Expansion in Emerging Markets: Fast industrialization and urbanization in Asia, particularly China and India, are driving demand for springs in various applications

Rising Demand for Electric Vehicles: Springs are used in various EV components, and the surge in EV production is likely to increase demand for high-performance springs

Innovation in Spring Materials: Developments in materials science are leading to stronger, lighter, and more corrosion-resistant materials, enhancing spring performance in harsh environments

Sustainability: Eco-friendly production procedures are becoming more important, with companies implementing recyclable materials and energy-efficient processes

Customized Springs: There is an increasing demand for bespoke springs tailored to specific applications, particularly in automotive, aerospace, and medical devices

This introduction provides a comprehensive overview of the spring manufacturing industry, covering its processes, classifications, materials, surface treatments, applications, and market prospects.