Stamping Industry Overview

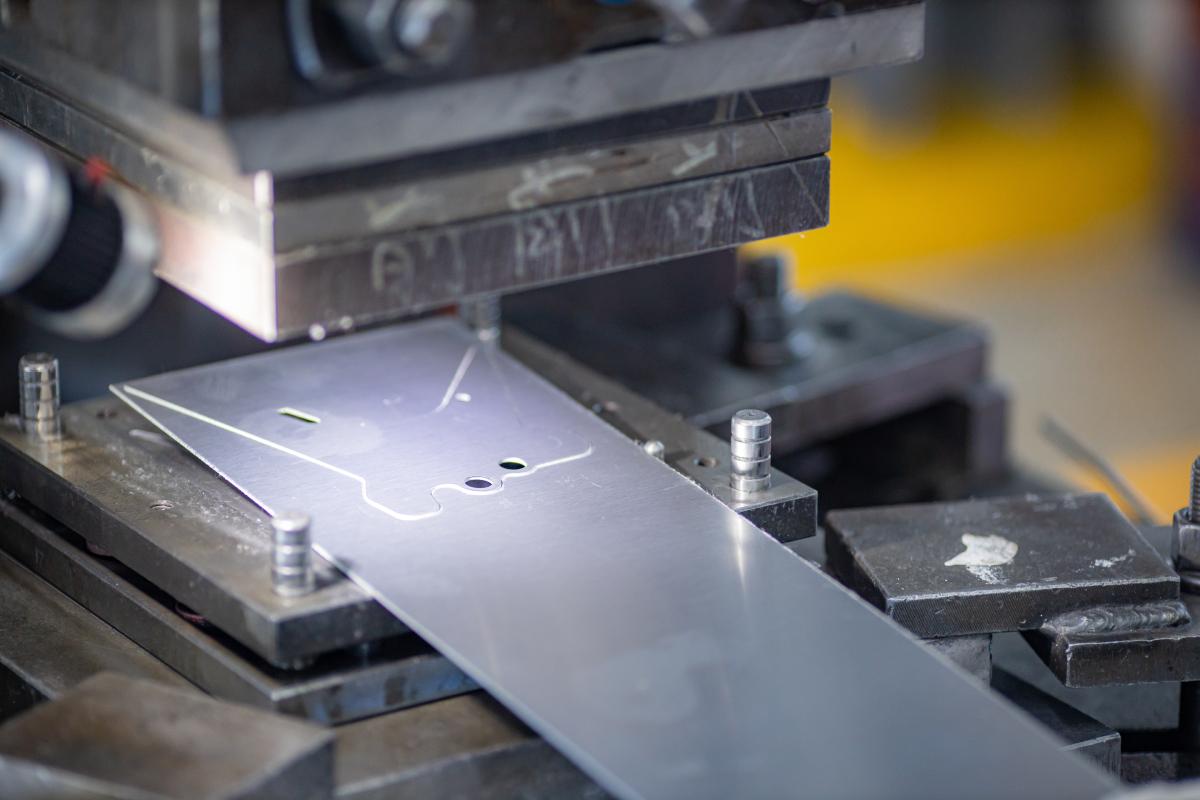

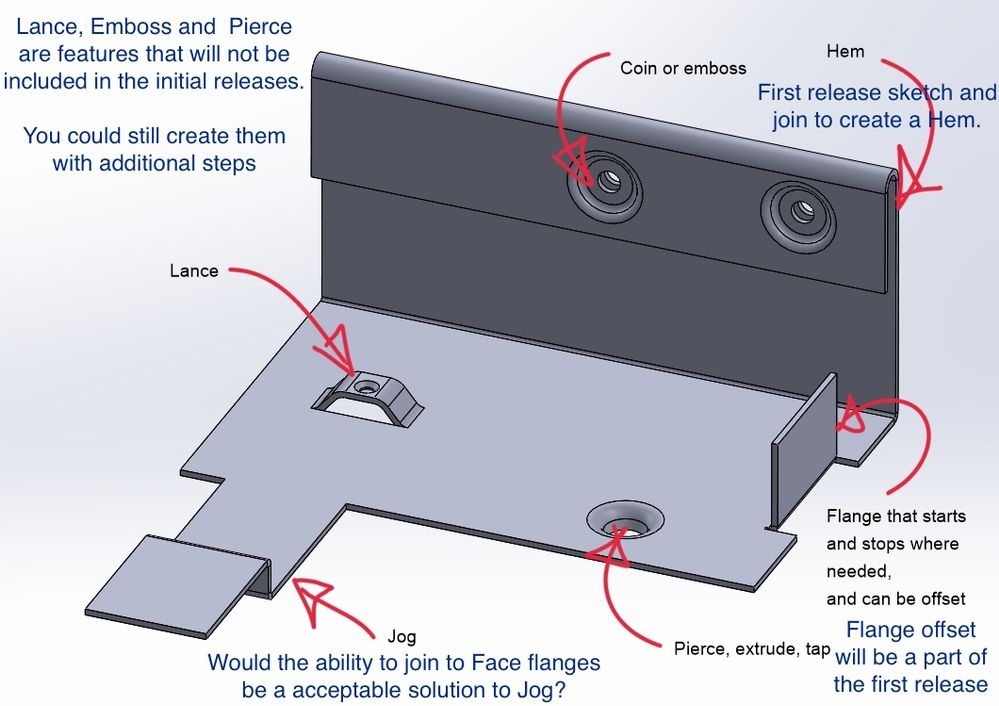

The stamping industry is a critical segment of the global manufacturing sector, specializing in the transformation of flat metal sheets or coils into precisely shaped parts through a variety of processes including blanking, embossing, bending, coining, deep drawing, and flanging

This industry is known for its versatility, efficiency, and the ability to produce high-quality components in large quantities.

Process Insights

The stamping process is diverse, with blanking being a significant segment, accounting for over 32.0% of the market share in 2023

Blanking is essential in the automotive industry for its precise and superior stamping capabilities, allowing for mass production of components with consistent dimensions. Embossing, the second-largest segment, is used to produce different patterns and sizes on sheet metal, enhancing stiffness, rigidity, and traction

Bending is a cost-effective process for low to medium quantities of metals and is utilized in various automotive applications

Coining, once used for minting coins, is now applied in metal stamping to achieve fine details in automotive designs

Press Type Insights

Mechanical presses dominate the market, holding a revenue share of almost 50.0% in 2023

They are characterized by fast and continuous pressure application, making them ideal for stamping applications, especially in high-volume production for industries like automotive

Servo presses are gaining prominence for their precision in metal forming processes, offering more accurate and flexible stamping operations

Thickness Insights

Sheet metal with a thickness of less than and up to 2.5 mm holds over 65.0% of the market share

This material is ideal for producing small, precise components for electronic devices and interior automotive components

Applications of Sheet Metal Stamping

Sheet metal stamping is widely used across various industries in China, including automotive, aerospace, electronics, appliances, and industrial equipment

The automotive industry relies heavily on stamping for body parts and structural components, while the aerospace industry uses it for aircraft components

Electronics and appliance industries also leverage stamping for casings, components, and structural parts

Market Growth and Trends

The global metal stamping market is projected to grow at a CAGR of 4.2% from 2024 to 2030

This growth is attributed to the continuous advancements in press technology, leading to enhanced speed, accuracy, and automation capabilities

The market is also influenced by the need for increased productivity and cost efficiency in metal stamping

China's Role in the Stamping Industry

China plays a significant role in the sheet metal stamping industry, offering competitive advantages in cost, precision, material availability, and production efficiency

With its extensive applications across various industries, sheet metal stamping continues to be a crucial manufacturing process in China, meeting the demands of both domestic and international markets

Conclusion

The stamping industry is a dynamic and essential part of modern manufacturing, with a significant impact on the production of components across multiple sectors. As technology advances, the industry continues to evolve, maintaining its position at the forefront of precision engineering and mass production.